-

Our Services

- New Industrialisation

-

IIOT

- IIOT

- Industrie 4.0 - Smart Enterprise

- Product Lifecycle Management Consultancy

- Intelligent Automatic Warehousing and Logistics

- Real-Time Manufacturing Tracking System

- Knowledge Based Engineering & CAD Solution

- Location Based Services and Location Analytics

- The HATCH

- Hong Kong Industrial Drone Technology Centre

-

AI & Robotics

- AI & Robotics

- AI Sheet Metal Surface Defect Detection Technology

- Product Innovation and Design Management

- Robotics Application

- Automation Feasibility Study

- 3D Automatic Processing

- Application and Research on Vision and Ultrasonic Inspection Assisted by Artificial Intelligence and Robotics

- Customized Intelligent and Cognition Automation Machine & System Development

- Autonomous Air-ground Cooperative Tunnel Inspector

- AR-Empowered Robot Control System (ARERC System)

- IoT-enabled Smart Toilet Bowl Cleaning System

- Novel Materials

-

Advanced Manufacturing Technology

- Advanced Manufacturing Technology

- 3D Scanning and Reverse Engineering Service

- Flexible Metallic Fiber Physical Porous Part Fabrication Technology

- Advanced Mould Cooling Technology and CAE Conformal Cooling Analysis

- Gas Atomisation Technology

- Dual Laser Metal Polishing Technology

- Advanced Additive Manufacturing, 3D Printing Technology, and Direct Manufacturing

- Diffusion Bonding Technology

- Electrically-Assisted Free Forming (EAFF) Technology for Customisation of Sheet Metal Parts

- Plastic Process and Machinery Technology

- Fashion and Garment Technology

- Computer Aided Technology (CAx)

- Watch Assembly Automation Technology

-

Digital Transformation

- Digital Transformation

- HKPC Digital DIY Portal

- 「FitEasy」Virtual Fitting Technology - For People with Disability

- Smart Solution

- Digital Transformation Support

- Research and Analytics

- Strategic IT Management

- Cyber Security

- Embedded Software System

- New Media and Learning Technology Development

- IT Industry Support

- DevOps Maturity Assessment and Consultancy Service

- Software Testing Automation Consultancy Service

- Blockchain Consulting Service

- Extended Reality (XR) technology and consultancy service

- Smart Living

-

Green Technology

- Green Technology

- HealthTech and Chinese Medicine

- Carbon Neutrality and Comprehensive Carbon Management

- Green Procurement

- Eco-Design & Manufacturing Consultancy Service

- Cleaner Production

- Advanced decolorisation process for landfill leachate

- Effective Utilisation of Resources

- Innovative Environmental Technology Development

- Food Technology

- Geron Technology

-

Corporate Sustainability

- Corporate Sustainability

- Manufacturing Technology (Tooling, Metals & Plastics) Recognition of Prior Learning (RPL) Mechanism

- Market Research and Analytics

- Business Innovation

- Sustainability-related standards and guidance

- Organisation Innovation Capability Development

- ESG and Sustainability Services

- District Innovation

- Customer Service Assessment

- Intellectual Property (IP) Protection and Management

- Support to Creative Industries

- Manufacturing Standards Consultancy Service

- Production Capacity Optimisation

- Cost of Quality

- Testing & Standards

- Price Concessions to SMEs

- Community

-

Support & Resource

- Technology Transfer

- SME Services

- Biz Expands Easy (BEE) Funding Portal

-

Support Centres

- Support Centres

- Celesphere

- Inno Space

- The HATCH

- Intellectual Property Services Centre

- Advanced Electronics Processing Technology Centre

- Green Living Laboratory

- Reliability Testing Centre

- Electromagnetic Compatibility Centre

- Plastics Technology Centre

- Smart Wearables, Watch & Clock Technology Centre

- Conformal Cooling Technology Centre

- Hong Kong Digital Testing Hub

- Hong Kong Industrial Drone Technology Centre

- Aqua Research Laboratory

- Advanced Materials and Intelligent Manufacturing Centre

- Hong Kong Joint Research Lab for Applications of Intelligent Automation Technology

- Future FoodTech Lab

- HKUST-HKPC Joint Research Lab for Industrial AI and Robotics

- Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR)

- Venues & Facilities

- Testing & Standards

- HKPC Spotlights

- HKPC Academy

- About US

-

LANGUAGE

LANGUAGE

IIOT

- Industrie 4.0 - Smart Enterprise

- Product Lifecycle Management Consultancy

- Intelligent Automatic Warehousing and Logistics

- Real-Time Manufacturing Tracking System

- Knowledge Based Engineering & CAD Solution

- Location Based Services and Location Analytics

- The HATCH

- Hong Kong Industrial Drone Technology Centre

AI & Robotics

- AI Sheet Metal Surface Defect Detection Technology

- Product Innovation and Design Management

- Robotics Application

- Automation Feasibility Study

- 3D Automatic Processing

- Application and Research on Vision and Ultrasonic Inspection Assisted by Artificial Intelligence and Robotics

- Customized Intelligent and Cognition Automation Machine & System Development

- Autonomous Air-ground Cooperative Tunnel Inspector

- AR-Empowered Robot Control System (ARERC System)

- IoT-enabled Smart Toilet Bowl Cleaning System

Advanced Manufacturing Technology

- 3D Scanning and Reverse Engineering Service

- Flexible Metallic Fiber Physical Porous Part Fabrication Technology

- Advanced Mould Cooling Technology and CAE Conformal Cooling Analysis

- Gas Atomisation Technology

- Dual Laser Metal Polishing Technology

- Advanced Additive Manufacturing, 3D Printing Technology, and Direct Manufacturing

- Diffusion Bonding Technology

- Electrically-Assisted Free Forming (EAFF) Technology for Customisation of Sheet Metal Parts

- Plastic Process and Machinery Technology

- Fashion and Garment Technology

- Computer Aided Technology (CAx)

- Watch Assembly Automation Technology

Digital Transformation

- HKPC Digital DIY Portal

- 「FitEasy」Virtual Fitting Technology - For People with Disability

- Smart Solution

- Digital Transformation Support

- Research and Analytics

- Strategic IT Management

- Cyber Security

- Embedded Software System

- New Media and Learning Technology Development

- IT Industry Support

- DevOps Maturity Assessment and Consultancy Service

- Software Testing Automation Consultancy Service

- Blockchain Consulting Service

- Extended Reality (XR) technology and consultancy service

Green Technology

- HealthTech and Chinese Medicine

- Carbon Neutrality and Comprehensive Carbon Management

- Green Procurement

- Eco-Design & Manufacturing Consultancy Service

- Cleaner Production

- Advanced decolorisation process for landfill leachate

- Effective Utilisation of Resources

- Innovative Environmental Technology Development

Corporate Sustainability

- Manufacturing Technology (Tooling, Metals & Plastics) Recognition of Prior Learning (RPL) Mechanism

- Market Research and Analytics

- Business Innovation

- Sustainability-related standards and guidance

- Organisation Innovation Capability Development

- ESG and Sustainability Services

- District Innovation

- Customer Service Assessment

- Intellectual Property (IP) Protection and Management

- Support to Creative Industries

- Manufacturing Standards Consultancy Service

- Production Capacity Optimisation

- Cost of Quality

Support Centres

- Celesphere

- Inno Space

- The HATCH

- Intellectual Property Services Centre

- Advanced Electronics Processing Technology Centre

- Green Living Laboratory

- Reliability Testing Centre

- Electromagnetic Compatibility Centre

- Plastics Technology Centre

- Smart Wearables, Watch & Clock Technology Centre

- Conformal Cooling Technology Centre

- Hong Kong Digital Testing Hub

- Hong Kong Industrial Drone Technology Centre

- Aqua Research Laboratory

- Advanced Materials and Intelligent Manufacturing Centre

- Hong Kong Joint Research Lab for Applications of Intelligent Automation Technology

- Future FoodTech Lab

- HKUST-HKPC Joint Research Lab for Industrial AI and Robotics

- Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR)

Plastic Processing Technology

Plastic Processing Technology

With a comprehensive range of plastics conversion processing machinery and equipment, PTC is well equipped to conduct research, process analysis and support plastic product manufacturers in the following areas:

Rapid Heating & Cooling Injection Molding Process

Rapid heating and cooling injection-moulding process utilizes a pressurized hot water control system to shorten the heating and cooling cycle time of the mould, resulting in a nearly perfect finish.

The high temperature inside the mold maintains the fluidity of resin and hence prohibits the polymer from freezing during the filling stage. This can avoid undesirable effects such as weldline, warpage, sink marks and different kinds of surface streaks.

Micro Cellular Foam (MuCell) Co-Injection Moulding Process

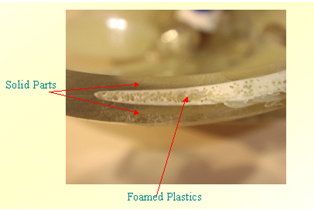

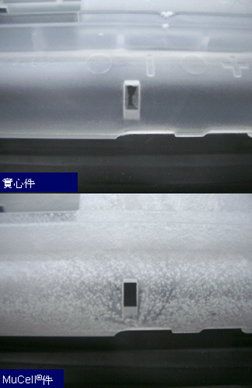

Incorporating the Micro cellular foam (MuCell) injection moulding technology with co-injection moulding technology. The foam cores produced by Micro cellular foam (MuCell) injection moulding can reduce the density, increase the dimensional accuracy and reduce distortion of the product, while the smooth skins produced by co-injection moulding can hide the rough foam cores and enhance the product appearance.

Micro Cellular Foam (MuCell) Injection Moulding

This process makes use of the physical foaming to produce micro cells of even size distribution. These structural improvements make the product superior to those produced by other foam injection moulding technologies in terms of properties.

Micro Injection

Micro plastic parts refer to the parts of plastic content weigh less than 0.1g. This kind of plastic parts is broadly applied in many areas. For example, micro switches, micro motors and sensors, gear wheels inside timepieces, latches and transmission parts have already adopted plastic to replace traditional metal parts. Furthermore, plastic can be also applied to micro optical lens, sensor discs, light guide plates and display panels. Medical device is one of the market that represents high growth potential, typical examples include medical parts which are implanted into body or blood vessels (e.g. audiphones) and the implanted parts made of biodegradable plastics.

Resin Blending

Resin blending is a method that mixes two different resins together at their melting temperatures to produce a resin composite of specilized material properties. This process allows to develop the degradable material and enhance the property of the polymer.

Our Services

Community

Support & Resource

HKPC Spotlights

HKPC Academy

COPYRIGHT© Hong Kong Productivity Council

FOLLOW US

SUBSCRIBE TO OUR NEWSLETTERS

Share the latest information of HKPC to your inbox

SIGNUP NOW